Tridan RBQ-5

General Information

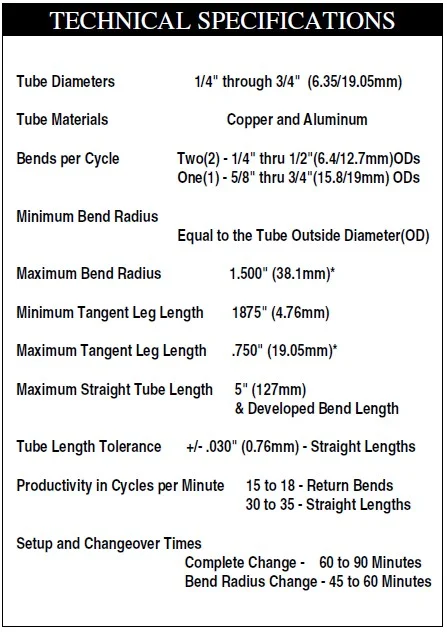

The Tridan Model RBQ-5 Qual-Ekon Return Bender is a fully Automatic mandrel type bender that has a saw cutoff and bends up to three (3) tubes per cycle. This machine is designed to produce 180 degree return bends and short straight lengths from level wound rolls of copper or aluminum tubing.

The Model RBQ-5 Qual-Ekon Return Bender is one of a family, of return benders built by TRIDAN. The Model RBV-1 Volutron Return Bender produces up to six(6) return bends per cycle, dependent upon tube diameter. The Model REXQ-4 Qual-Ekon Combination Return, Elbow, and Dual 90 Degree Crossover Bender has the same capacity specifications as the RBQ-5; however, as the name implies, it will produce elbow and dual 90 degree crossovers in addition to elbows & return bends.

The RBQ-5 was designed specifically for the lower-to-moderate volume coil manufacturer, who previously could not justify the cost and/or the output of return benders producing six to ten bends per cycle.

The production application of the TRIDAN Model RBQ-5 is to fabricate short 180 degree bends, known as return bends, "J" Bends (a 180 degree bend with two different leg lengths) elbow bends or short straight lengths directly from level-wound coiled tubing of copper or aluminum having outside tube diameters between 1/4" (6.35mm) and 3/4" (19.05mm). Random straight length of tubing may also be employed; however, the productive output will be reduced and between 12" and 16" (305/406mm) of tubing will be wasted per straight length. It is a fully integrated system consisting of an adjustable-length Tube Feeding and Straightening Section, Tube Bending Section, and Cutoff/Bend Ejection Section. Supporting equipment includes a Tube Decoiling System. The Control System is designed in such a manner that all operations are sequenced Fully automatically or may be individually placed under manual control.