Tridan HBPA

General Information

The Tridan Hand Fed Power Assist Hairpin Bender is designed for the production of hairpin benders from straight pre-cut lengths of copper or aluminum tubing. Upon manual feed and clamping of the tubes, the HBPA then performs the bend with the assistance of a hydraulic cylinder.

The Model HBPA-4 Hand Fed Hairpin Bender is one of two hand fed hairpin benders built by TRIDAN to augment our line of fully automatic hopper and level-wound coil fed hairpin benders. The other hand fed hairpin bender

is the Model HBVQ-4. Both benders were designed to meet and fulfill production requirements of lower-to-moderate volume hairpin production for pre-cut straight tube lengths.

The TRIDAN Model HBPA-4 Hairpin Bender is a heavy-duty hand fed hairpin bender with its bending function hydraulically powered, automatic internal lubrication of the tube through the bending mandrels, and partial

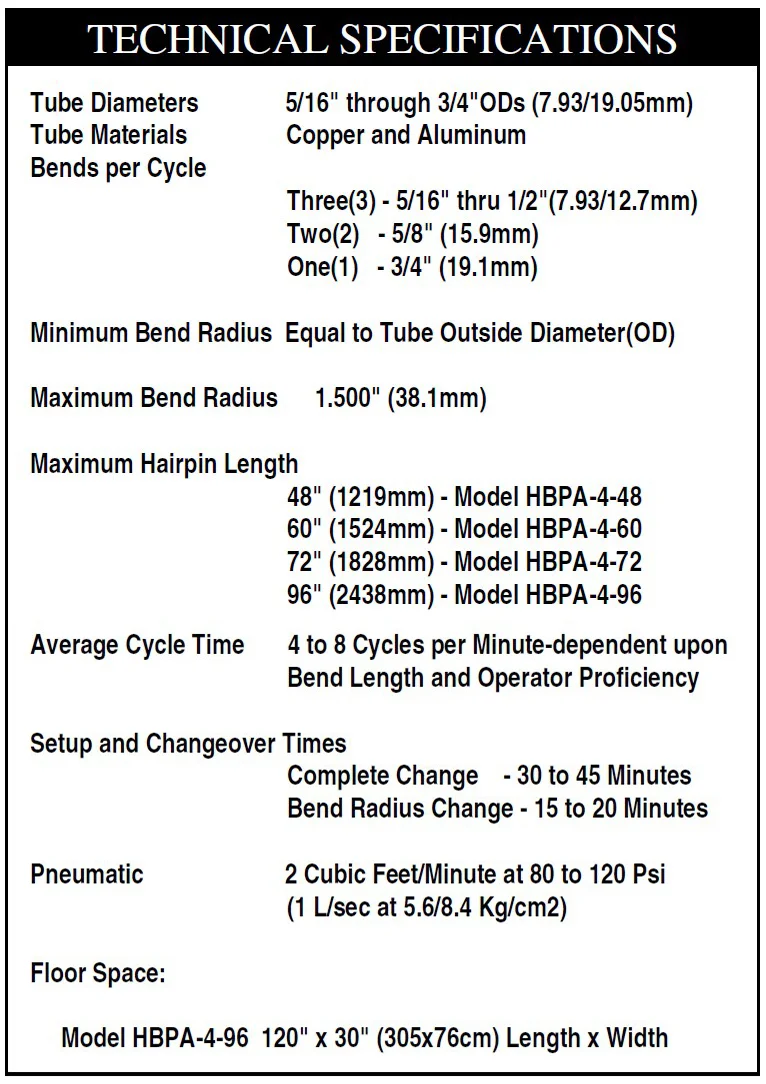

hairpin bend ejection. It is designed for copper and aluminum tubing having outside diameters' between 5/16"(7.94mm) and 3/4"(19.05mm). The HBPA-4 bends three(3) hairpins per cycle on tube diameters between

5/16"(7.94mm) and 1/2"(12.7mm), two(2) per cycle with 5/8"(15.9mm) OD, and one(1) hairpin per cycle on 3/4"(19.1mm) OD. The Model HBPA-4 is built on a heavy-duty structural steel frame, with a work line height of 36 inches (91.4cm) from floor level. The Bend Head Mechanism, Follower (wiper) Block Assembly, Length Adjustment-Stripper Rail, Mandrel Rod(s)and Mandrel Rod Retainer are plate-mounted atop the benders

frame.

The bend head mechanism also contains the Bend Die, Bend Die Clamp Block, and the Operational Handle. The tube clamping mechanism is a positive latching eccentric with all pivot points fitted with needle bearings to minimize clamping force requirements. The bend head hydraulic cylinder is activated upon latching of the

tube clamping mechanism.

DOWNLOAD BROCHURE