Tridan AHBS

General Information

The Tridan Model AHBS Hopper Fed Hairpin Bender, Short Lengths was designed for processing of hairpin bends From short pre-cut straight length tubes. The operator places the straight tubes into the hopper, they are then fed into the loading section, inserted on the bend mandrels, bent and stripped from the machine automatically.

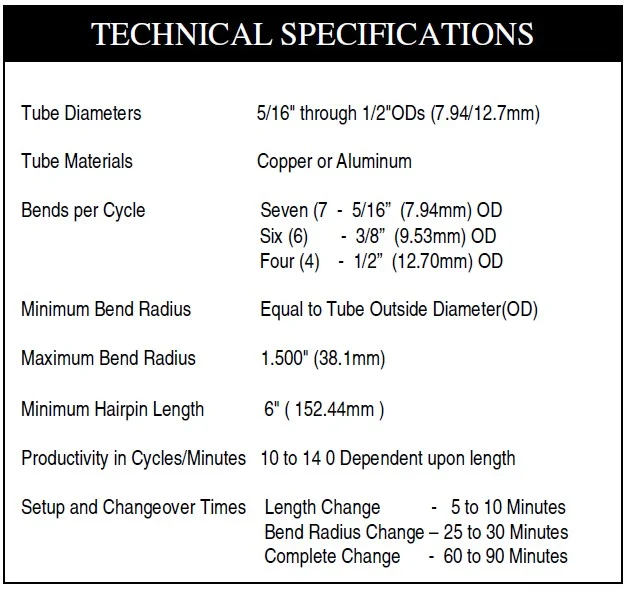

The production application of the TRIDAN Model AHBS-1 is to produce hairpin bends from short pre-cut straight tube lengths of copper or aluminum having outside diameters between 5/16"(7.94mm) and 1/2"(12.7mm). The AHBS-1 bends seven (7) hairpins per cycle on 5/16"(7.94mm) OD tubing, six(6) per cycle on 3/8"(9.525mm)OD, and four(4) per cycle on 1/2"(12.7mm) OD. It is a fully integrated system consisting of a Hopper Feed Unit and Hairpin Bender. The Control System is designed in such a manner that all operations are sequenced fully automatically or may be individually placed under manual control. The Hopper Feed Unit is designed to meter and feed the required number of tube lengths to the Model AHBS-1 Hairpin Bender, which forms the hairpin bends, and ejects the completed hairpins. The bender and hopper are integrated together, and mounted on a machined base plate, which also serves as the top of the weldment-constructed hydraulic reservoir. This over-sized reservoir is an integral part of the machine's frame, and is furnished as standard with a liquid level gauge and thermometer.

DOWNLOAD BROCHURE